PU Sealant and Trim Adhesive

One component moisture curing high-modulus polyurethane

Benefits

• High mechanical performances

• Permanent elastic

• Paintable

Uses

Ideal for bondingand waterproofing GRP trims but canalso be used for interior and exterior waterproof joints in building and metal constructions. For gluing, sealing, mounting and anchoring in building applications. For use in metal and mechanical construction, ship building and container sealing joints, refrigeration plants, automotive, caravan, mobile home, aircraft and the railway industry.

Directions of Use

Cut the cartridge seal and screw on the nozzle, which should be cut to your required size. Using a skeleton gun, apply the sealant firmly into the gap or joint ensuring a good solid fill. If required place masking tape along edges, removing within 10 minutes of application.

Limitations

• Not suitable for PE, PP, PTFE, neoprene and bituminous surfaces

• Not suitable for continuous water immersion

• Avoid exposure to high levels of chlorine

• Avoid contact with alcohol and other solvent cleaners during cure

• Do not use in the presence of curing silicone sealants

• Sealant may bubble if applied in a high moisture vapour environment.

Surface Preparations and Finishing

Surfaces must be clean, dry and free from dust, grease and other loose material. Priming is not usually necessary. Adhesion tests prior to SX Premium Polyflex HM Polyurethane

It bonds to all common building materials, is permanently elastic and has excellent grab and gap filling properties making it ideal for use in a wide range of building and maintenance situations.

Benefits

- Flexible and elastic.

- Bonds to concrete, brick, mortar, wood, metals, glass, stone, ceramics, resins and plastics.

- Excellent grab and non-slip.

- Fast curing rate.

- Good weather and water resistance.

- Permanently flexible and elastic.

- Non corrosive.

- Provides excellent mechanical resistance.

- Resistance to most common chemicals.

- Good sea water resistance.

- Can be used as an easy flow flooring grade for all concrete saw cuts and floor slab expansion joints, where abrasion resistance is required.

Uses

Ideal for sealing and bonding metal panels and trims. Also, ideal for expansion joint sealing in concrete panels and floor joints, while being good for sealing in applications subject to vibration and mechanical abrasion. Great for a multitude of sealing and bonding applications in the construction and engineering industries.

For use in high traffic floor joints such as those found in garage forecourts, warehouse, factory floors, sports arenas, shopping centres etc. Perfect for:

- Bonding in container fabrication.

- Bonding/fixing cabinets, shower trays, mirrors, ceramics.

- Bonding and sealing flashings, roof tiles, gutters, architrave, skirting, panelling, mouldings and acoustic tiles.

- Filling and sealing internal and external cracks and gaps around window and door frames.

- Forming gaskets in ducting and sealing between metal components.

- Fabrications and shop fitting.

- Flexible draught proofing.

Surface Preparations and Finishing

Ensure substrate is clean, dry and free of all contaminants such as dirt, oil, grease, cement laitance, old sealants and poorly bonded paint coatings which could affect adhesion of the adhesive/sealant.

Directions of Use

Cut the cartridge seal and screw on the nozzle, which should be cut to your required size. Place it in a standard sealant gun. Apply in triangular beads, strips or spots at intervals of a few centimetres each. Use hand pressure only to fix the components to be bonded into position before skinning of the adhesive occurs.

Apply the sealant firmly into the gap or joint ensuring a good solid fill. If necessary, use temporary adhesive tapes, wedges, or supports to hold the assembled components together, removing within 10 minutes of application. Provide temporary support for heavy bonded items until full curing, which takes 24-48 hours.

Limitations

- Not suitable for PE, PP, PTFE, neoprene and bituminous surfaces.

- Not suitable for continuous water immersion.

- Avoid exposure to high levels of chlorine.

- Avoid contact with alcohol and other solvent cleaners during cure.

- Do not use in the presence of curing silicone sealants.

- Sealant may bubble if applied in a high moisture vapour environment.

Paintability

This product can be painted over when cured.

| SKU | GEN-PU-Adhesive |

|---|---|

| Stock Type | Warehouse Fulfilled |

| Brand Name | Rubber4Roofs |

| Color | Grey |

-

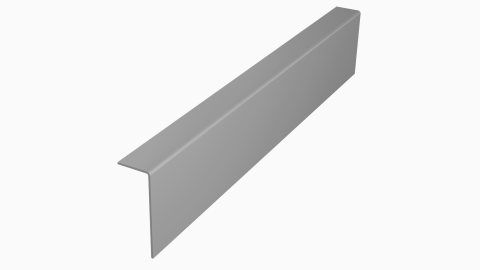

GRP Simulated Lead Flashing Trim (C100)£16.80 £14.00

GRP Simulated Lead Flashing Trim (C100)£16.80 £14.00